By clicking “Accept All Cookies”, you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts Cookies Policy.

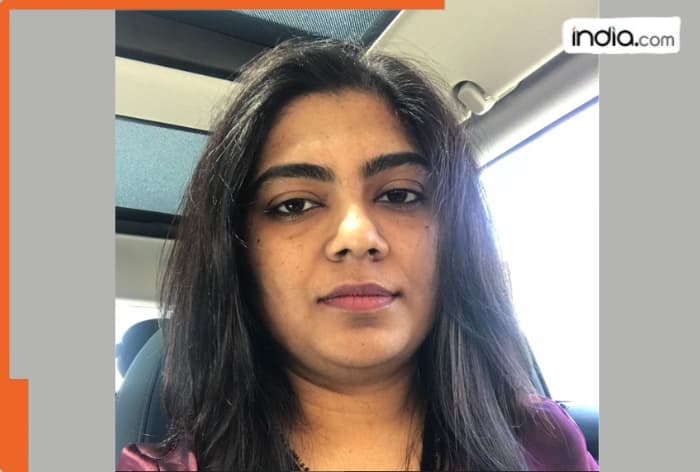

Glory Shrivastava is a distinguished controls engineer specializing in green energy and industrial automation systems, based in Hopkinton, Massachusetts. With a Master of Science in Electrical Engineering from Oklahoma State University, Stillwater, OK, USA and a Bachelor of Technology in Electronics & Instrumentation Engineering from Dr. M.G.R University in Chennai, India, Glory brings over a decade of expertise in control systems integration and optimization. Her professional journey spans various aspects of controls engineering, from Burner Management Systems (BMS) to cutting-edge green energy solutions, making her a notable figure in the field of sustainable technology and industrial automation.

Q1: What drives your passion for controls engineering, particularly in the green energy sector?

A: I feel like if you do something, anything, that you really enjoy, you don’t really need a driving force to do it. Controls engineering plays a crucial role in the modern world of advancement and technologies, regardless of the industry. The green energy sector presents unique challenges that require innovative control solutions. I find it incredibly rewarding to work on systems that contribute to a more sustainable future while pushing the boundaries of what’s possible in control system integration. The complexity of green energy systems, particularly in areas like electrolysis and renewable energy, demands continuous innovation in control strategies. This constant evolution keeps me engaged and motivated to develop more efficient and reliable solutions.

Q2: How has your experience with Burner Management Systems influenced your approach to green energy controls?

A: My decade of experience with BMS and the oil and gas industry in general, has been invaluable in understanding complex safety systems and regulatory requirements. This background has helped me develop robust control solutions that prioritize safety without compromising the efficiency of a system. The principles of reliable system design and safety protocols are universal, whether you’re working with traditional energy systems or innovative green technologies. Working with BMS taught me the importance of precise control, safety interlocks, and system reliability – principles that are crucial in green energy applications. This experience has been particularly valuable in developing comprehensive safety protocols and ensuring regulatory compliance across different types of energy systems.

Q3: Could you describe your approach to optimizing control systems for maximum efficiency?

A: My approach to system optimization is multi-faceted, focusing on both technical excellence and practical usability. I begin by thoroughly analyzing system requirements and identifying key performance indicators. Using advanced PLC programming techniques and sophisticated HMI interfaces, I implement control strategies that maximize efficiency while maintaining system stability. This involves careful consideration of various parameters such as temperature, pressure, and power consumption, along with implementing advanced monitoring and control algorithms. I also emphasize the importance of data collection and analysis for continuous improvement, using tools like Power BI for visualization and trending of system performance metrics.

Q4: What role does safety play in your engineering philosophy?

A: Safety is the cornerstone of my engineering philosophy. I started my career with designing safety systems for refinery equipment which left a lasting impact on my thought process. Throughout my career, I’ve been deeply involved in risk analysis and HAZOP activities, ensuring compliance with international standards like IEC, NFPA, and UL. I believe in integrating safety considerations from the initial design phase through implementation and operations. This includes developing a safe design, selecting apt and quality instrumentation, implementing robust safety instrumented systems, and ensuring proper documentation and training. My experience with various safety protocols and standards has taught me that a proactive safety approach not only protects personnel and equipment but also improves overall system reliability and performance.

Q5: How do you approach collaboration with cross-functional teams?

A: Effective collaboration is essential for successful project execution. I’ve developed a systematic approach to working with diverse teams, including power electronics specialists, mechanical engineers, and process engineers. This involves establishing clear communication channels, regular cross-functional meetings, and shared documentation practices. I believe in creating an environment where different perspectives are valued and integrated into the final solution. My experience in managing I&C teams has taught me the importance of balancing technical expertise with strong interpersonal skills, ensuring that all stakeholders are aligned toward project goals.

Q6: What tools and technologies do you rely on most in your work?

A: My technical toolkit is comprehensive and continuously evolving. I work extensively with various PLC platforms including Allen-Bradley, Siemens, and Modicon, programming in multiple languages from Ladder Logic to Structured Text. For system visualization and control, I utilize advanced HMI platforms such as FactoryTalk Studio and Simatic WinCC. AutoCAD plays a crucial role in developing electrical schematics and panel layouts. I also emphasize the importance of staying current with emerging technologies and industry standards, regularly updating my skillset to include new tools and methodologies that can enhance system performance and reliability.

Q7: How do you ensure project success when dealing with complex control systems?

A: Success in complex control system projects requires a methodical approach to planning and execution. I start with thorough documentation, including detailed P&IDs, electrical schematics, and control narratives. Project management is key – I focus on clear milestone definition, resource allocation, and risk management. Regular stakeholder communication and progress tracking help identify and address potential issues early. I also emphasize the importance of comprehensive testing, including FAT and SAT procedures, to ensure system reliability before deployment. This systematic approach has helped me successfully deliver numerous complex projects throughout my career.

Q8: What challenges do you frequently encounter in implementing green energy control systems?

A: Green energy systems present unique challenges in terms of system stability, efficiency, and integration. One major challenge is designing control systems that can handle variable inputs while maintaining consistent output quality. This requires sophisticated monitoring and control strategies, along with robust safety protocols. Another significant challenge is integrating new technologies with existing infrastructure while ensuring optimal performance. I approach these challenges through careful system design, extensive testing, and continuous monitoring and optimization of system parameters.

Q9: How do you stay current with industry trends and technological advancements?

A: Staying current in our rapidly evolving field is crucial. I maintain active involvement in professional organizations like IEEE, Women in Manufacturing (WiM), the International Society of Automation (ISA), where I served as Secretary of the Automatic Controls and Robotics Division in 2024 and also as General Secretary from 2010 to 2011 of the OSU student chapter. These roles provide opportunities to exchange ideas with industry leaders and learn about emerging technologies. I also regularly participate in technical conferences, webinars, and training programs to expand my knowledge base. Additionally, my background in academic research continues to influence my approach to problem-solving and innovation in the field.

Q10: What advice would you give to the next generation of controls engineers?

A: For those entering the field of controls engineering, I recommend building a strong foundation in both theoretical principles and practical applications. Understanding fundamental control theory is essential, but equally important is gaining hands-on experience with different platforms and technologies. I encourage aspiring engineers to seek out mentorship opportunities and get involved in professional organizations through internships and co-ops opportunities. It’s also crucial to develop strong problem-solving skills and maintain curiosity about new technologies and methodologies. The field of controls engineering, particularly in green energy, is constantly evolving, so a commitment to continuous learning is essential for long-term success.

Glory Shrivastava is a senior controls engineer with extensive experience in industrial automation and green energy systems. Her expertise spans PLC programming, HMI development, and safety system implementation. She holds a Master’s degree in Electrical Engineering from Oklahoma State University and has contributed significantly to advancing control system technologies in sustainable energy applications. Glory is an active member of several professional organizations. Her work focuses on optimizing control systems for maximum efficiency while maintaining the highest safety standards. Throughout her career, she has demonstrated leadership in implementing innovative solutions for complex control challenges in the green energy sector.

FIRST PUBLISHED: 23rd October 2023

For breaking news and live news updates, like us on Facebook or follow us on Twitter and Instagram. Read more on Latest Science and Technology News on India.com.